Checkpoint 1

Last Updated: Jan 23, 2026

In Checkpoint 1, you will tune the PID gains for wheel velocity, improve the firmware odometry calculations, and implement a motion controller. The controller will take in waypoints and automatically follow the path.

Contents

- Contents

- Task 1.1 Wheel Calibration

- Task 1.2 PID Tuning

- Task 1.3 Improve firmware

- Task 1.4 Motion Controller

- Checkpoint Submission

Task 1.1 Wheel Calibration

The calibration program checks the polarity of the encoders and motors, then performs a wheel speed calibration. The resulting data are printed to the terminal and stored in the MBot’s non-volatile memory.

The calibration data consists of:

- Encoder Polarity: Describes whether the encoder’s count increases or decreases when a positive PWM signal is applied to the motor.

- Motor Polarity: Refers to the relationship between the motor’s actual rotation direction and the command it receives.

- For example: if the right wheel’s polarity is -1, and you command it to “rotate forward at 1 m/s,” the wheel will rotate forward, which might seem counterintuitive given the negative polarity.

- The reason is that the z-axes of the wheels point outward. According to the right-hand rule, the positive rotation direction for the right wheel corresponds to a backward rotation relative to the MBot’s body frame.

- For example: if the right wheel’s polarity is -1, and you command it to “rotate forward at 1 m/s,” the wheel will rotate forward, which might seem counterintuitive given the negative polarity.

- Slopes and Intercepts: Define the linear relationship between the PWM duty cycles and the actual speeds of the wheels.

TODO

Open one terminal with Minicom to monitor the calibration output, and use another terminal to flash the calibration firmware to the Pico. Run the calibration several times and collect the resulting data for analysis. This task focuses on analyzing the system’s performance.

# terminal 1

sudo minicom -D /dev/mbot_debug -b 115200

# terminal 2

cd ~/mbot_firmware_ros/build

sudo mbot-upload-firmware flash mbot_calibrate_classic.uf2

To quit minicom, first press CTRL + A, then press X, then press Enter to quit. Alternatively, you can simply close the terminal window.

Pro Tips:

- Close your current Minicom session before starting a new one (prevents port errors).

- Stay organized: Don’t hoard terminal windows. Keep only what you need open so you don’t get confused.

Once you’ve finished collecting data, remember to flash the firmware back to the control board.

cd ~/mbot_firmware_ros/build

sudo mbot-upload-firmware flash mbot_classic_ros.uf2

Report the motor calibration with variance for the robot on a concrete floor (like in the lab).

Questions to Consider:

1) How much variation is there in the calibration?

2) What do you think is the source of variation?

Task 1.2 PID Tuning

There are 3 drive modes and 3 control modes in firmware source code.

Drive Modes

- PWM Control — You directly send PWM commands to individual motors.

- Wheel Velocity Control — You send wheel velocity commands to individual wheels.

- Robot Velocity Control — You send robot body velocity commands

vxandwz.

Control Modes

- Feedforward (FF) Control Only

- PID Control Only

- Feedforward + PID Control

The drive mode is automatically selected based on the type of control command you send:

- If you publish to

/cmd_vel, Robot Velocity Control mode will be selected, meaning the robot will interpret commands as body velocities.

The control mode is automatically selected when you flash the calibration script. The default mode is Feedforward + PID Control. During calibration, the script reads the default parameters from mbot_firmware_ros/include/config/mbot_classic_default_pid.h and writes them to FRAM.

You can tune the PID gains at runtime via the ROS parameter server.

You may notice that only wheel-level PID gains are exposed. This is because Robot Velocity Control is implemented on top of Wheel Velocity Control:

- The commanded body velocities (vx, wz) are first converted into individual wheel velocities using the robot kinematics.

- These wheel velocity commands are then tracked using the selected control mode (FF, PID, or FF+PID), which ultimately generates PWM commands for the motors.

TODO

Tune the PID values to achieve a desired system response.

How to tune?

-

First, modify the values in

include/config/mbot_classic_pid.yaml.This file contains pre-tuned values that are the same as those in

mbot_classic_default_pid.h. However, these default parameters may not be compatible with your specific robot and could cause your MBot to perform poorly when using the teleop controller. - After modifying the values in the yaml file, run the command below to load the new configs:

cd ~/mbot_firmware_ros ros2 param load /mbot_control_node include/config/mbot_classic_pid.yaml - If you want to check whether the values are actually loaded, run:

ros2 param dump /mbot_control_node- If you see the values you set, it means the new PID gains have been applied to the MBot and written to the FRAM. You can run test now!

- The PID values will persist after rebooting. However, if you flash the calibration again, the calibration script will overwrite your tuned PID gains by the values in

mbot_firmware_ros/include/config/mbot_classic_default_pid.h, and you’ll need to reload the YAML file to restore them by running the command from step 2.- After you are satisfied with your PID gains, if you really want to check whether the gains persist after rebooting, you can verify this as follows:

- Open a terminal and start Minicom.

- In another terminal, flash the firmware (not calibrationty). Before the data table is printed, the firmware will first display all the saved parameters, check the PID values there.

- After you are satisfied with your PID gains, if you really want to check whether the gains persist after rebooting, you can verify this as follows:

How to test?

We provide two Python scripts for testing:

mbot_firmware_ros/python-tests/test_wheel_pid.py: This script drives the robot and prints the target vs. actual wheel speeds in the terminal. Use it as a starting point, modify it to drive longer or more complex paths, then use it to make comparisons and collect data for your plots.mbot_firmware_ros/python-tests/drive_square.py: This script drives the robot in a square pattern. Use the taped square on the lab floor and check whether your robot can follow the square and return to the starting point.- Note that every robot is slightly different in size. Not only are the PID gains different for each robot, but so are the hardware parameters.

- Go to

~/mbot_firmware_ros/include/configand openmbot_classic_config.h. You may adjust theDIFF_BASE_RADIUSvalue (in meter), this value represents the robot’s base radius. The base diameter is the distance from the center of one wheel to the center of the other. If your robot isn’t driving in a proper square, this parameter may be inaccurate. - If you modified the robot’s base radius, remember to recompile the firmware and flash it to the control board.

cd ~/mbot_firmware_ros/build cmake .. make sudo mbot-upload-firmware flash mbot_classic_ros.uf2

Tip #1: You don’t have to make all control mode drive perfectly. The required plots are only for comparison, to show how the PID controller improves performance.

Tip #2: If the robot doesn’t drive a perfect square, it also might not be your controller, it could be due to inaccurate odometry. Continue to Task 1.3 to explore ways to improve it further.

Plot of time vs. velocity with robot responding to a step command of 0.5 m/s for the FF model, PID controller model and FF + PID controller (3 traces on one plot).

Questions to Consider:

1) Which wheel controller performs the best and the worst, why?

2) Is there any improvement we can make?

Task 1.3 Improve firmware

Odometry estimates your robot’s position and orientation by integrating wheel encoder measurements over time. In the firmware code we currently use a simple dead-reckoning approach, which may not provide the most accurate results.

While the PID controllers help maintain accurate wheel speeds, you can add further enhancements to improve overall motion performance.

TODO

- Use

~/mbot_firmware_ros/src/mbot_odometry.cas a starting point to understand how odometry is calculated, and consider adding improvements. For example, you could incorporate gyro readings and implement gyrodometry for better accuracy. - Read

~/mbot_firmware_ros/src/mbot_classic_ros.c. This is the source code of the firmware uf2 file you compiled. The PID controller implementation starts around line 309, if you want to add features such as filters, this is a good place to begin.

How to test your changes?

- Compile your code and flash it to the control board:

cd ~/mbot_firmware_ros/build cmake .. make sudo mbot-upload-firmware flash mbot_classic_ros.uf2 - Use teleop to drive the robot over a known distance and angle, then check your odometry values:

ros2 topic echo /odom --field pose - Run the

mbot_firmware_ros/python-tests/drive_square.pyscript and see if the robot’s performance has improved.

Describe what you added to the firmware and explain your reasoning.

Task 1.4 Motion Controller

The motion controller takes a series of waypoints as input and generates velocity commands as output to navigate through them.

In this task, you will implement a rotate-translate-rotate controller. This is a high-level strategy that uses a PID controller to precisely execute each movement: rotating to the goal, driving forward, and rotating to the final orientation.

The PID controller in the firmware is used to control the wheel speed, while the PID controller in this task is used to control the traveled distance.

TODO

- Go to the Class GitLab page, fork the

mbot_ros_labsrepository to your group. This repository contains the code for checkpoints. - Create a workspace directory named

mbot_ros_labs, and clone the forked repository into a subdirectory calledsrc:cd ~ mkdir mbot_ros_labs cd ~/mbot_ros_labs git clone your_url src - Implement the controller in the file

mbot_setpoint/src/motion_controller_diff.cpp. You can search for the keyword “TODO”, all the functions you need to complete are marked with “TODO” and numbered. Follow the numbering sequence as you implement them. - Once you finish writing your code, build and source the workspace:

cd ~/mbot_ros_labs colcon build --packages-select mbot_setpoint source install/setup.bash- Important: You must source the workspace in every relevant terminal after each build. If you don’t, ROS will keep using the old code, and your changes will not take effect.

Tip: You don’t have to strictly follow the provided TODOs to fill up the blanks in the code, if you want to implement a more sophisticated controller, feel free to do so. The template is intended to make things easier, not necessarily to achieve the best possible performance.

How to test?

- Run the motion controller

ros2 run mbot_setpoint motion_controller_diff - Publish the waypoints. By default, this node publishes a square with 1-meter sides:

ros2 run mbot_setpoint square_publisher

Pro Tips:

- Always reset odometry between tests. You can either 1) Run the command below or 2) Press the RST button on the control board.

ros2 service call /reset_odometry std_srvs/srv/Trigger - Why Reset Odometry?

- The motion controller and square_publisher both operate in the odom frame right now.

- The Problem: Your robot rarely finishes exactly at (0, 0, 0). If a run ends at (0, 1, 0) and you restart without resetting, the robot still thinks it is at (0, 1, 0). When you send the first waypoint, the robot won’t drive forward. It will calculate a path from (0, 1, 0) to (1, 0, 0), likely causing an unexpected turn or diagonal movement.

Describe your motion control algorithm.

Questions to Consider:

1) Include a plot of your robot’s estimated pose as the robot is commanded to drive a 1m square 4 times.

2) Include a plot of the robot’s linear and rotational velocity as it drives one loop around the square.

Checkpoint Submission

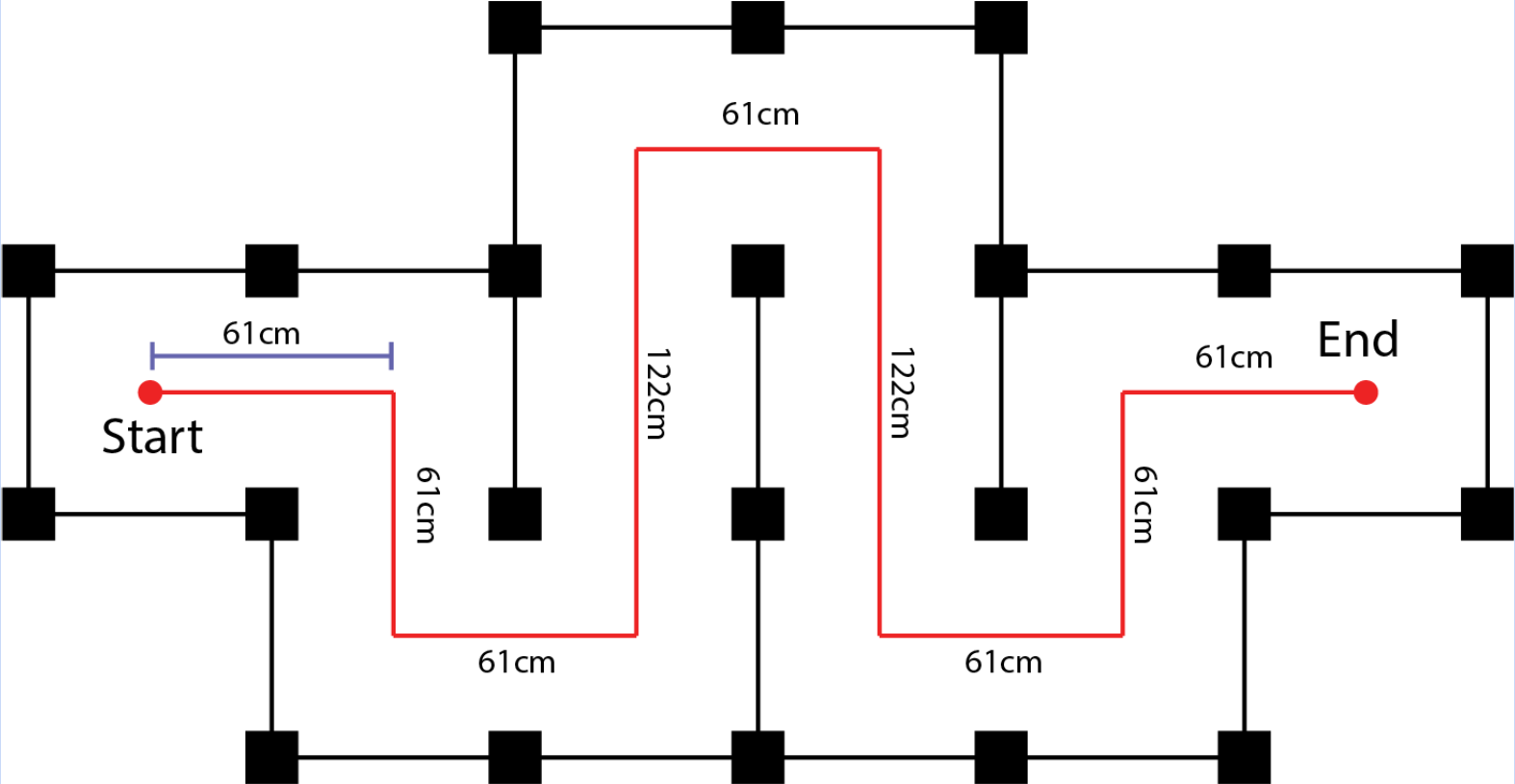

- Run you motion controller to drive the path show in the image above. Include the following items in your submission:

- Record a video of the robot attempting the path at a slow speed (~0.2m/s & pi/4 rad/s) and a high speed (~0.8m/s, pi rad/s) and provide a link to it. The robot motion does NOT need to be perfect

- Include a plot of the (x, y) odometry position as the robot executes the path at both speeds.

- Write a short description of your controllers (1/2 page) and any features we should be aware of.